Sustainability at Rasch

Environmentally friendly renovation, simple and professional

Innovative, attractive and sustainable

How our company combines ecological standards with technological leadership

|

We face up to the responsibility of manufacturing products that promote people's well-being and conserve nature for future generations.

Sustainability and product attractiveness are no longer a contradiction. In addition to design and technology leadership, innovative products are increasingly characterised by ecological compatibility and a respectful approach to nature. This claim is firmly anchored in our brand essence and forms the foundation for our entrepreneurial activities.

This includes not only the standards we set for our products, but also the way we treat people, outside and inside the company, the recycling of raw materials and the careful use of valuable resources.

Sustainable manufacturing

Our rasch greenline is manufactured in a resource-saving way from 100% recycled pulp and PET fibres and in environmentally friendly packaging.

|

With the completely new rasch greenline, we are expanding our product range and making a contribution to the sustainable use of our environment and natural resources.

Phthalate-free manufacturing

At the turn of the year 2022/2023, we switched to a purely phthalate-free manufacturing of wallpapers and had our products certified in a comprehensive test in a testing laboratory.

Harmful substances such as phthalates or plasticisers are added to materials to make them more supple and flexible. The field of application is diverse and they can be found almost everywhere in living spaces.

We comply with the concentration limits for phthalates subject to the standardised testing procedure and are allowed to label our products with the Phthalate free seal of quality. We thus meet the high standards for the ecological compatibility of our products and phthalate-reduced indoor air.

This was an important milestone in the further development of the company in terms of sustainability and healthy living. We are thus facing up to our social responsibility and making an important contribution to energy- and resource-saving construction and renovation.

Resource management

As a manufacturing company that sells its products worldwide, we naturally have an impact on our environment. Therefore, we see the most resource- and environmentally-friendly management possible as an essential pillar of our actions.

|

As a traditional family business that has been successful for several generations, we have always attached great importance to sustainability.

Energy management systems

The basis of our energy management system is continuous improvement. This means that we constantly strive to optimise our processes and technologies in order to permanently minimise energy use in manufacturing. We rely on systematic monitoring and evaluation of our major energy consumers in order to identify potential for energy savings and initiate appropriate measures.

Our goal is to minimise energy consumption sustainably through our energy management system while strengthening our competitiveness. The ISO 50001:2018 certification is an important milestone on this path, as it provides us with a clear structure and an internationally recognised standard.

Wastewater treatment

Our wastewater treatment is an integral part of our sustainability efforts. In 2022, we proudly achieved that almost 50% of our wastewater generated on the farm has undergone efficient chemical-physical wastewater treatment internally.

This advanced technology removes harmful substances and contaminants from wastewater before it is released into the environment. In this way, we ensure that the discharged water meets environmental standards and has no negative impact on water bodies and ecosystems. At the same time, we regularly train our employees in the handling of fresh water and wastewater to promote the responsible use of resources.

PVC recycling systems

With the aim of acting in a forward-looking manner and minimising our ecological footprint, we have decided to increasingly rely on PVC recycling systems and to dispense with the use of plasticisers.

As an alternative to PVC, we have developed products that are free of PVC and plasticisers. These are exclusively acrylic-based and offer an environmentally friendly solution for our customers. These new products will replace conventional vinyl wallpaper in the long term, helping to promote sustainable living.

In addition, we are increasingly using water-based paints that are free of solvents, thereby reducing the release of harmful substances into the environment. We would also like to emphasise that in addition to our PVC-free products, our non-woven wallpapers and paper wallpapers with backing paper are also 100% recyclable.

We are confident that these advances in our manufacturing will help us achieve our sustainability goals and offer environmentally friendly solutions to our customers.

Waste management

Waste management is a central issue in our company. We are actively committed to minimising the environmental impact of our manufacturing and using resources efficiently. An important focus is on dealing with our largest recyclable material stream, wallpaper residues, including approach rolls and edge trims.

To ensure that these materials and the production-related plastisol residues are not simply disposed of but are given a new use, 100% of them are sent for material recycling. In this way, we close the cycle and contribute to the conservation of resources. The disposal and recycling of wallpaper remnants is monitored by an independent environmental auditor to ensure that we meet our targets and comply with sustainability standards.

In 2022, we achieved an impressive separate collection rate of almost 98% for waste and recyclables. This measure not only reduces the amount of waste that ends up in landfills, but also helps to conserve natural resources.

We are continuously working to improve our recycling routes to increase internal processing rates and realise the full potential of materials to achieve more sustainable waste management and minimise our environmental footprint.

Residual item recycling

By selling remnants in our Factory Outlet to end users, we enable efficient use of resources and help reduce waste. Instead of simply disposing of these residual items, we give them a second chance. By returning remnants to the economic cycle, we not only avoid waste, but also reduce the demand for new products. This helps to reduce greenhouse gas emissions associated with the manufacturing and transport of new goods. By offering these products at attractive prices, we can target new customer segments and increase sales. At the same time, we promote conscious consumer behaviour and make sustainability tangible for our customers.

Heating energy for printing processes

Our company is actively committed to sustainability and the efficient use of heating energy in our printing processes. We are aware that these processes inevitably and unavoidably generate waste heat. Instead of letting this energy go unused, we have developed innovative solutions to use the waste heat effectively.

In addition to using the heating energy for our own purposes, we go one step further. We are working on giving part of the generated heat to the municipal energy supply. Through this cooperation, we are helping to improve local energy efficiency and contribute to the sustainable energy supply of our community.

CO2 reduction

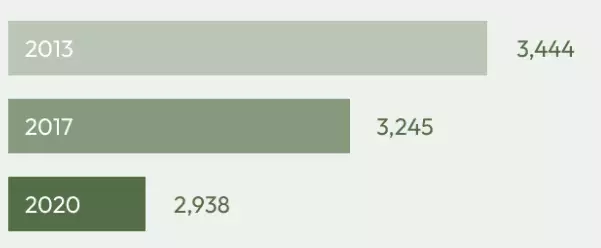

Between 2013 and 2020, we have reduced our CO2 emissions per roll of wallpaper produced at our Bramsche site by 15 percent.*

|

This corresponds to an amount of 506 grams of CO2/wallpaper roll

Our vision for the future

We are committed to taking responsibility for our planet, environment and climate, and contributing to a sustainable future. We want to create more value for our customers, consumers, neighbours and our company - while reducing our environmental footprint.

Green-Deal: Our milestones

|

2025

10% more CO2 neutral manufacturing

|

2035

30% CO2 neutral manufacturing

|

2050

50% more CO2 neutral manufacturing

That is why we are constantly driving forward various sustainability issues. For example, we strive to use cardboard adhesives made from renewable raw materials in order to minimise the use of synthetic adhesives. We also use films made from recycled materials to reduce the need for new resources. We also place great emphasis on environmental compatibility in the manufacturing of our structures. We use PVC-free structures to minimise the environmental impact of harmful chemicals. All these measures help us to continue reducing our waste and CO2 emissions. We hope that with our commitment and entrepreneurial actions we can inspire other companies to work together to make a positive impact on the environment.

Social commitment

We are involved in various social projects and initiatives

As a partner of the first hour of the "Westphalian Peace Aid for Children - a donation initiative of terre des hommes", we show social commitment as a company from the Osnabrück-Münster region, inspired and motivated by the Westphalian Peace.

With the aim of giving needy children the chance of a better future and actively creating a culture of peace, our donations particularly benefit children who are on the run and in war and crisis zones.

Whether it is medical aid for injured and traumatised child soldiers, educational opportunities or legal advice for refugees - the international children's relief organisation "terre des hommes" supports children and young people worldwide and in Germany and gives them the chance of a self-determined and fulfilled life.

Further information at:

www.friedenshilfe-fuer-kinder.de

FAQ

|

Sustainability in the manufacturing of wallpapers: Answers to frequently asked questions.

The importance of sustainability is becoming increasingly important, not only for the environment, but also for the economy and society. As a wallpaper manufacturer, it is important to implement sustainable practices to reduce the environmental impact and improve the social impact of the business. Here you will find answers to frequently asked questions about sustainability and how we can help create a sustainable future.

What does sustainability mean?

Sustainability means that the needs and demands of the present can be met without compromising the ability of future generations to meet their own needs. In the economic sphere, it means that economic growth, stability and profitability are guaranteed, but that resources and the environment are used responsibly so as not to endanger the well-being of humanity and the planet in the long term.

What are sustainable materials?

Sustainable wallpaper manufacturing begins with the selection of sustainable materials. In the manufacturing of our wallpapers, we have been using almost exclusively FSC ®-certified substrates since 2009. Our backing paper and backing fleece are made from the wood of sustainably managed forests.

Water-based inks and adhesives are also sustainable materials in wallpaper manufacturing.

We also use environmentally friendly and recycled materials for our packaging.

How can a wallpaper manufacturer produce more sustainably?

There are different approaches how we can produce more sustainably as a wallpaper manufacturer. We focus in particular on the aspects of energy management systems, waste water treatment, waste management, PVC recycling systems, certifications and standards as well as residual item recycling. We have explained the individual areas in more detail under the Resource Management section on this page.

What are the advantages of sustainable wallpapers?

Sustainable wallpapers have many different benefits from environmental protection to healthy living to promoting innovation.

For example, sustainably produced wallpapers help reduce the ecological footprint. By using environmentally friendly materials, fewer resources are used and less waste is produced. The use of water-based paints, for example, has the advantage that fewer chemical ingredients are used, which contributes positively to the health of the home and the indoor climate.

The growing focus on sustainable wallpapers also has the advantage that we as a company are paying more attention to optimising ourselves more and more and are increasingly focusing on innovations for the more sustainable manufacturing of wallpapers.